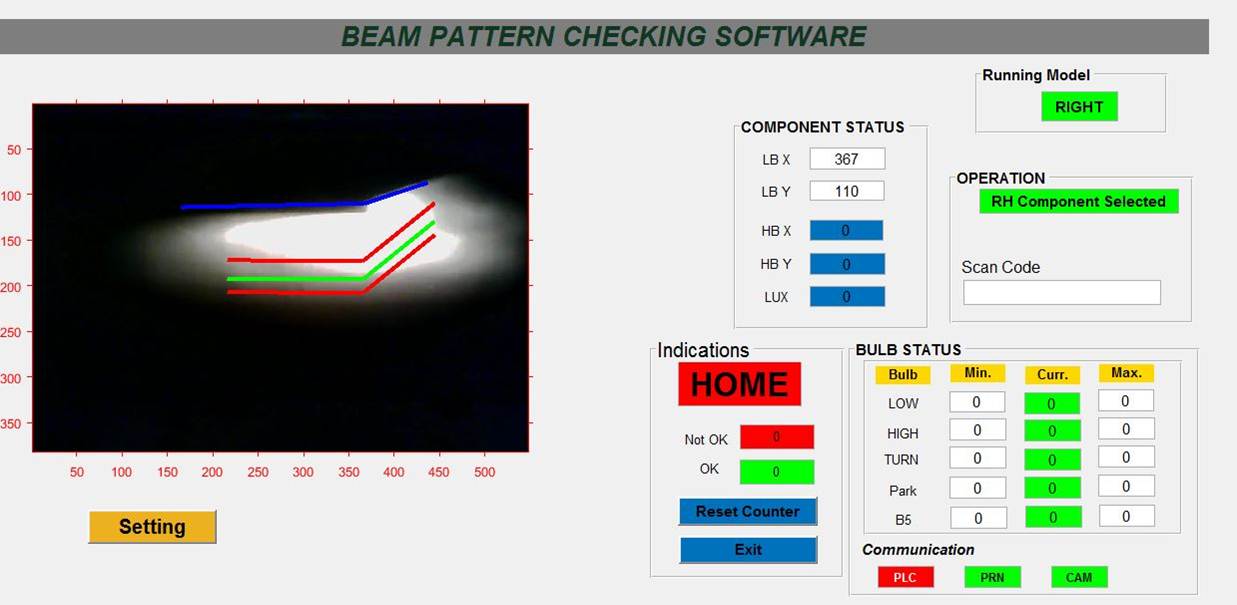

Light Testing(Aiming Machine) is developed for headlamp pattern testing. Using camera our software recognise the pattern of lamp and compare it with the master light pattern.Some of the features of Aiming system are as below

--Camera and Printer Interfacing.

--Data fetching from PLC and HMI.

--Master control of Software

--Red and green color for OK and NG

--Barcode printing after successful cycle completion

--Live video streaming to adjust the pattern

--Master settings page for multiple variants

--Run the program as per master selection

--Master pattern auto selection as per low beam and high beam

This is orientation and position analysis vision application developed by JV technologies. It finds the angle with tthe master position of part and also show the direction whather it is clockwise or anticlockwise.Features of this machine are

--Camera and PLC communication.

--Data fetching from PLC and HMI.

--If missed the valve postion it will show rejected indication

--Incremental count after every succesful cycle

--Live video streaming to see motor position and rotation

--Master settings page for multiple variants

--Autorun the program as per master selection

--Can set the exposer and other lightening parameters

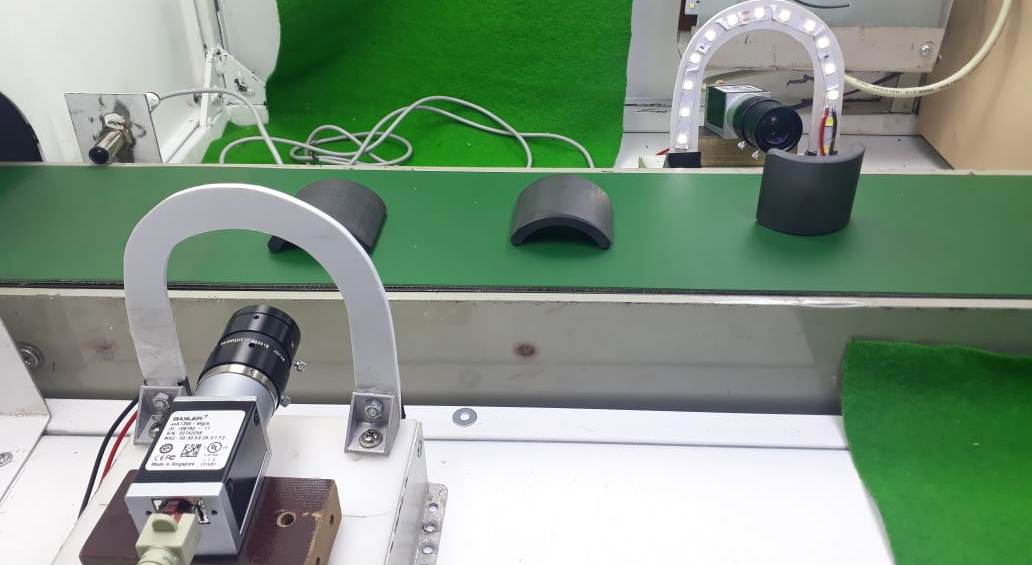

While manufacturing the parts, quality analysis is one of the most important and time consuming part. For the quality testing of parts we developed machine which having

--Dent, Damage, Chip off analysis

--Conveyor based system.

--All sides camera gives one result OK or NG sample

--Red and green color for OK and NG

Air filters and Oil filters are one of the important part in automobile sector. For Blockage detection manual method is not helpful so we pass the light and tested it using camera

--Part variation in diameter and height

--Automatically adjust the focus according to height.

--20X zoon view

--Live video streaming to adjust the pattern